Shafts gears bolts studs connecting rods spindles tool holders.

4140 round bar hardness.

Typical tensile strength ranges from 114 000 psi annealed condition up to 156 000 psi pre hard quench and tempered condition.

It has a tensile strength of 150 000 psi yield strength of 130 000psi and approximately 35 45 elongation.

Alloying elements and thermal treatments such as quenching and tempering greatly influence the hardness and strength of the steel.

This steel is offered in a wide range of conditions including but not limited to.

Cold drawn annealed hot roll heat treated heat treated turned ground and polished.

Tempering 2 hour 205.

The 4140 product is also available in a precision ground surface finish 25rms max.

Also known as chrome moly steel 4140 alloy steel resists fracturing from repeated stress.

The purpose of the molybdenum is to add uniformity of hardness and strength to this alloy.

These sheets and bars are hardened for increased abrasion and impact resistance.

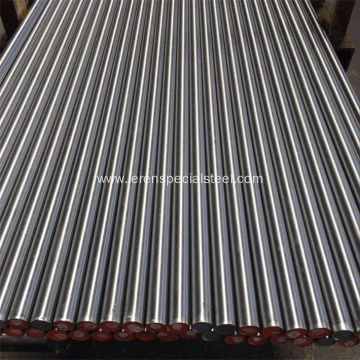

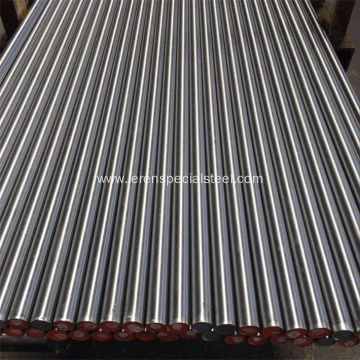

M k s 4140 steel round bar is a cold drawn annealed steel of relatively high hardenability due to its chromium content.

Some sizes may be calcium treated.

Aisi 4140 and 4150 is a medium carbon chromium molybdenum alloy steel.

4140 is a 1 chromium molybdenum medium hardenability general purpose high tensile steel generally supplied hardened and tempered in the tensile range of 850 1000 mpa condition t 4140 is now available with improved machinability which greatly increases feeds and or speeds while also extending tool life without adversley affecting mechanical properties.

4140 alloy steel round is an cold drawn annealed steel of relatively high hardenability with its chromium content provides good hardness penetration and the molybdenum imparts uniformity of hardness and high strength.

Similar to alloy grade aisi 4130 chrome moly alloy steel but with a slightly higher.

4140 responds readily to heat treatment and is relatively easy to machine in the heat treated condition.

4140 alloy steel round has good strength and wear resistance excellent toughness coupled with good ductility and the ability to resist.

It provides good hardness penetration and the molybdenum imparts uniformity of hardness and high strength.

Aisi sae 4140 alloy steel is a chromium molybdenum alloy steel specification widely used in general purpose high tensile steel for components like axles shafts bolts gears and other applications.

Alloy 4140 aisi 4140 is one of the most popular direct hardening cr mo alloy steel plates that have the ability to develop an extensive range of hardness and strength.

4140 alloy steel round responds well to heat treatment and is relatively easy to machine in the annealed condition.

Temperature 4140 steel hardness.

4140 alloy round bar.

In the annealed condition bars are supplied to a hardness of hb 207 approximately.

Material 4140 heat treat.